Description

Diagnostic mode

GlobeCore technology for diagnostic evaluation of transformers status is based on measuring some parameters by means of sensors, calculating other important parameters in reliance on these data, and transmitting all the results to the end user.

Interpretation of the results of online measurements of transformer parameters is available in the web application. We can always see what range measured and calculated values are within. But critical damage can develop in a matter of days and hours, and if the deterioration of parameters is observed on a day off work, or the transformer is very far away, you may never get a change to purify and dry the oil. Specifically for such cases, TOR-5 unit is equipped with a system for drying and filtering the insulating oil. When the transformer parameters reach the values set by the operator, TOR-5 automatically switches from the diagnostic evaluation mode to the insulating oil filtration and drying mode.

GlobeCore monitoring technique is based on using the relative humidity of insulating oil. Water can enter the transformer from the environment, for example, due to seal leaks; therefore, TOR-5 system measures the following parameters by means of sensors once a minute, 24 hours a day, 7 days a week:

A high-precision hydrogen sensor is additionally used as an indicator of transformer malfunctions. Hydrogen is formed in oil as one of the first gases already at the temperature of 150 degrees Celsius and accounts for up to 59% of all the gases released during the decomposition of oil molecules. Therefore, the content of this gas in insulating oil is a rather informative parameter for diagnostic evaluation of possible transformer malfunctions, in particular, occurring partial discharges. With partial discharges in oil, the weakest hydrocarbon bonds are broken through ionization with accumulation of hydrogen.

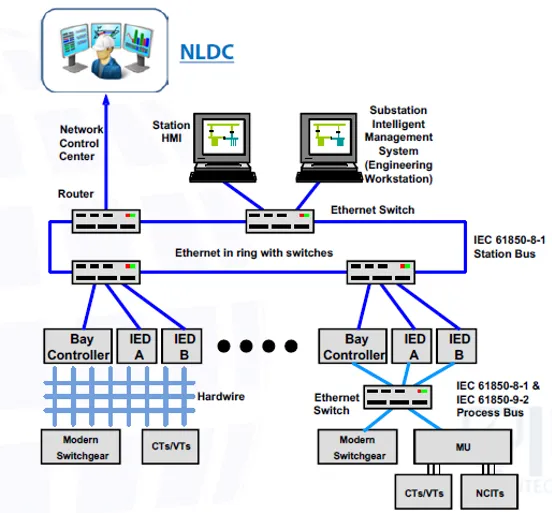

All measured data are transmitted via the Internet to a cloud server using a high-speed router. The router contains specialized software run in Linux environment. This software receives several analyzed parameters from sensors via Modbus/RS485 protocol and transfers them via HTTPS protocol. The router is connected to the Internet via any 2G/3G/LTE mobile network available at the location of the equipment.

On the cloud server, other parameters are calculated using special formulas and give more complete information about the transformer status:

Oil Drying and Filtration mode

In this mode, the oil is taken from the transformer bottom; next, it is sequentially pumped through a filter with the filtration fineness of ten microns and three adsorbers (sorbent cartridges) each of which contains 15 kilograms of aluminosilicate sorbent consisting of granules with a microporous structure. Using a filter, mechanical impurities are removed from the oil, and the aluminosilicate sorbent absorbs and retains water molecules in its crystals. After that, pure and dry oil is fed to the top of the transformer tank. The process of absorbing and entrapping the water does not require heating the oil and runs with the same efficacy regardless of the temperature. The pumping speed is 30 liters per hour, and the oil is processed without disconnecting the transformer, regardless of the time of day, weather conditions, or the presence of maintenance staff.

After the oil parameters return to normal, TOR-5 unit automatically switches back from the oil filtration and drying mode to the parameters monitoring mode.

Due to the fact that the water in the transformer is in a state of constant migration from oil to paper insulation and vice versa, the circulation of oil through the adsorbers allows removing the water not only from the oil, but also from the paper insulation. Thus, owing to TOR-5 system, the transformer remains dry throughout its service life.

Standard Complete

A standard complete set of TOR-5 system includes:

Specification

Advantages

Benefits

Diagnostic mode

GlobeCore technology for diagnostic evaluation of transformers status is based on measuring some parameters by means of sensors, calculating other important parameters in reliance on these data, and transmitting all the results to the end user.

Interpretation of the results of online measurements of transformer parameters is available in the web application. We can always see what range measured and calculated values are within. But critical damage can develop in a matter of days and hours, and if the deterioration of parameters is observed on a day off work, or the transformer is very far away, you may never get a change to purify and dry the oil. Specifically for such cases, TOR-5 unit is equipped with a system for drying and filtering the insulating oil. When the transformer parameters reach the values set by the operator, TOR-5 automatically switches from the diagnostic evaluation mode to the insulating oil filtration and drying mode.

GlobeCore monitoring technique is based on using the relative humidity of insulating oil. Water can enter the transformer from the environment, for example, due to seal leaks; therefore, TOR-5 system measures the following parameters by means of sensors once a minute, 24 hours a day, 7 days a week:

- temperature of transformer top and bottom oil;

- active water in transformer top and bottom oil;

- relative humidity of transformer top and bottom oil;

- ambient air temperature;

- relative humidity of ambient air.

A high-precision hydrogen sensor is additionally used as an indicator of transformer malfunctions. Hydrogen is formed in oil as one of the first gases already at the temperature of 150 degrees Celsius and accounts for up to 59% of all the gases released during the decomposition of oil molecules. Therefore, the content of this gas in insulating oil is a rather informative parameter for diagnostic evaluation of possible transformer malfunctions, in particular, occurring partial discharges. With partial discharges in oil, the weakest hydrocarbon bonds are broken through ionization with accumulation of hydrogen.

All measured data are transmitted via the Internet to a cloud server using a high-speed router. The router contains specialized software run in Linux environment. This software receives several analyzed parameters from sensors via Modbus/RS485 protocol and transfers them via HTTPS protocol. The router is connected to the Internet via any 2G/3G/LTE mobile network available at the location of the equipment.

On the cloud server, other parameters are calculated using special formulas and give more complete information about the transformer status:

- water content in transformer top and bottom oil;

- water content in solid insulation at transformer top and bottom;

- breakdown voltage of oil;

- oil quality index.

Oil Drying and Filtration mode

In this mode, the oil is taken from the transformer bottom; next, it is sequentially pumped through a filter with the filtration fineness of ten microns and three adsorbers (sorbent cartridges) each of which contains 15 kilograms of aluminosilicate sorbent consisting of granules with a microporous structure. Using a filter, mechanical impurities are removed from the oil, and the aluminosilicate sorbent absorbs and retains water molecules in its crystals. After that, pure and dry oil is fed to the top of the transformer tank. The process of absorbing and entrapping the water does not require heating the oil and runs with the same efficacy regardless of the temperature. The pumping speed is 30 liters per hour, and the oil is processed without disconnecting the transformer, regardless of the time of day, weather conditions, or the presence of maintenance staff.

After the oil parameters return to normal, TOR-5 unit automatically switches back from the oil filtration and drying mode to the parameters monitoring mode.

Due to the fact that the water in the transformer is in a state of constant migration from oil to paper insulation and vice versa, the circulation of oil through the adsorbers allows removing the water not only from the oil, but also from the paper insulation. Thus, owing to TOR-5 system, the transformer remains dry throughout its service life.

Standard Complete

A standard complete set of TOR-5 system includes:

- transformer parameters monitoring section (two sensors for moisture content and active water measurement, a hydrogen sensor, a top oil temperature sensor, a relative humidity and ambient temperature sensor, a heater for creating the temperature difference between input and output oil, a high-speed router);

- transformer oil processing section (three sorbent cartridges, a transfer pump, a pressure sensor for monitoring the filter clogging rate, an electronic oil meter, a float sensor for oil spill in the tray, an oil level sensor in the transformer tank);

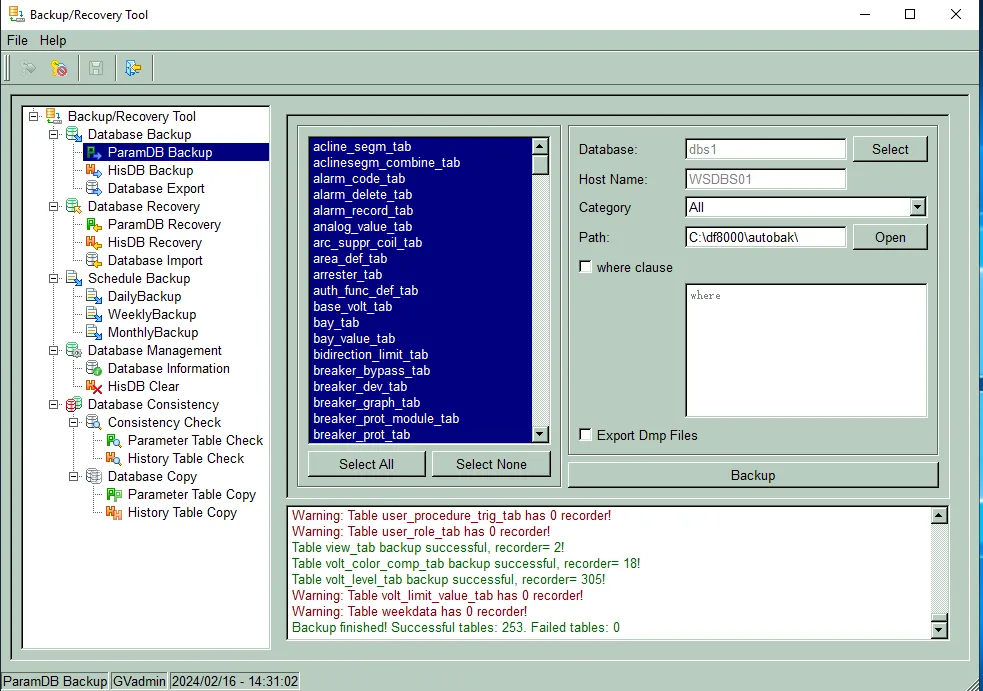

- web application that is hosted in a cloud service or on a virtual server in Linux environment. The web application receives data from TOR-5 units, accumulates them in the database, performs the necessary calculations, and provides the user on a real-time basis with the initial parameters received from the sensors and the parameters calculated using the formulas.

Specification

| Item | Value |

| Performance, L/h | 30 |

| Amount of water adsorbed, L | 9 |

| Amount of sorbent in one adsorber, kg | 21 |

| Output pressure, bar | 2 |

| Oil feeding height in relation to outlet fitting, m | 20 |

| Maximum power requirement, V, not more than | 500 |

| Electric Current Parameters | |

| Number of phases | 3p+1N+PE |

| Voltage, V | 380 |

| AC with frequency, Hz | 50 |

| Attachment Dimensions | |

| Oil inlet, DN | 20 |

| Oil outlet, DN | 20 |

| Dimensions, not more than | |

| length, mm | 1,180 |

| width/width including a subframe, mm | 350/550 |

| height/height including a subframe, mm | 2,035/2,085 |

| Weight, kg, not more than | 500 |

Advantages

- Low relative cost of the system. The price of new transformers and the losses caused by emergency failure of operating transformers reach hundreds of thousands and millions of dollars. And the cost of TOR-5 system accounts for only a small part of those expenses which makes the purchase and usage thereof a profitable investment.

- The system solves three challenges: determining the important parameters of transformers online, filtering and drying the insulating oil, as well as informing the user about its operation and the operation of the transformer in a prompt manner.

- TOR-5 system is suitable for servicing new and aged oil-filled transformers, as well as multipurpose transformers.

- Compact size. The system consists of the minimum number of components required for efficient operation which are placed in a single 115 centimeters wide, 208 centimeters high, and 35 centimeters long housing.

- The service life of the system is commensurate with the service life of the transformer due to the reliable protection of all components from damage and atmospheric precipitation.

- Convenient use of the web application. The web page displays a list of substations and transformers for each substation. The program also includes display of transformers on the map with representation of measurements and calculations in the form of graphs and charts. By choosing an object, one can get complete information about the oil condition for the entire period after installing TOR-5 system near the transformer, or for a selected period of time.

- Easy connection. After the preparatory stage, it takes a few minutes to connect the system to the transformer.

- The oil is processed automatically without disconnecting the transformer.

- Remote monitoring. Even while on vacation, the head of the electric power company or an employee of the service subdivision can log into the system from any workplace and get to know the transformer fleet status without awaiting the laboratory result and leaving for the equipment operation site.

- More complete information and assessment of transformer status change dynamics. Due to ongoing data acquisition, the transformer status change dynamics can be assessed which makes TOR-5 system more informative compared to periodic laboratory analyses.

Benefits

- Extended service life of new transformers for decades. With regard to older transformers, TOR-5 system makes it possible to determine based on oil aging dynamics when it is necessary to carry out repairs or to take the equipment out of operation in proper time avoiding an emergency.

- Increased timing between maintenance services for transformers due to preventive processing of insulating oil.

- Saved money due to ceasing to use laboratory analyses when obtaining more complete and immediate information of transformer status.

- Reduced expenses for insurance of transformers. The failure probability of a transformer equipped with TOR-5 system is considerably lower than that of a transformer not equipped with this kind of system. In such cases, an insurance policy usually costs less.

- Decreased number of skilled staff involved (sampling specialists, laboratory employees, operators of insulating oil filtration and drying units, etc.).

- Environmental conservation. A failed transformer causes an environmental disaster through a spill, fire, and even an explosion. TOR-5 system by GlobeCore allows avoiding these situations and preventing the environmental pollution associated with transformer emergencies

Inquiry - TOR-5 - Click to view details